All Technosoft drives/motors include a non-volatile EEPROM memory. Its role is to:

| • | Keep the setup data in a dedicated area named setup table together with a user programmable application ID, which helps you quickly identify the setup data uploaded from a drive/motor. |

| • | Store the TML motion programs and their associated data like the cam tables needed for electronic camming applications. |

| • | Keep the product ID of each drive/motor and the required firmware ID for the programmed application. |

Remark: The required firmware ID indicates that the actual drive/motor firmware ID must have the same number and a revision letter equal or higher. For example if the required firmware ID is: F000H, the actual drive/motor firmware ID must be F000H or F000I, or F000J, etc.

The Drive/Motor EEPROM Programmer is a tool specifically designed for production, through which you can:

| • | Program fast and easy the EEPROM memory of any Technosoft drive/motor with all the data needed to run a specific application. These data are grouped into a unique file named software file (with extension .sw) |

| • | Check EEPROM data integrity by comparing the information read from the drive/motor memory with that read from a .sw software file |

| • | Write protect a part or the entire EEPROM memory. |

| • | Get information about the drive/motor configuration ID including the product ID, the firmware ID and the application ID |

The Drive/Motor EEPROM Programmer is included in both the EasySetUp and EasyMotion Studio installation packages and is automatically installed with them. However, it may also be installed separately. To launch the Drive/Motor EEPROM from Windows Start menu execute: “Start | Programs | EasySetUp | Drive/Motor EEPROM Programmer” or “Start | Programs | EasyMotion Studio | Drive/Motor EEPROM Programmer” depending on which installation package you have used. You can also start the Drive/Motor EEPROM Programmer from the main folder of the EasySetUp / EasyMotion Studio by executing “eepromprog.exe”.

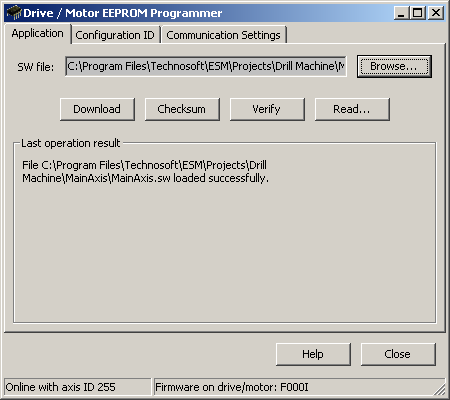

The Drive/Motor EEPROM Programmer has 3 tabs: Application, Configuration ID and Communication Settings

In the Application tab you select a .sw software file. Use the Download button to program it into the drive/motor EEPROM memory. Use the Verify button to check if the information stored in the drive/motor EEPROM is identical with that from the selected .sw file. Press the Checksum button to compute the sum modulo 65536 of all the data from a .sw file. The checksum result may be used by a master during the application initialization to validate that data from a drive/motor EEPROM memory is correct and complete. For example, the host can ask a drive/motor to return the checksum for each block of continuous data from the EEPROM, according with the .sw file. By adding the results returned by the drive/motor, the host obtains a global checksum which must match with the value got when the Checksum button is pressed. Use the Read… button to save the contents of the whole EEPROM memory in a .sw file.

The Drive/Motor EEPROM Programmer signals with an OK inside a green disk that the:

| • | Download operation is correctly executed |

| • | Verify operation, gives a match between the .sw file and the drive/motor EEPROM contents |

| • | Read operation is successfully ended and the .sw file is created |

Otherwise, an ERROR inside a red disk is displayed together with a message explaining the error type.

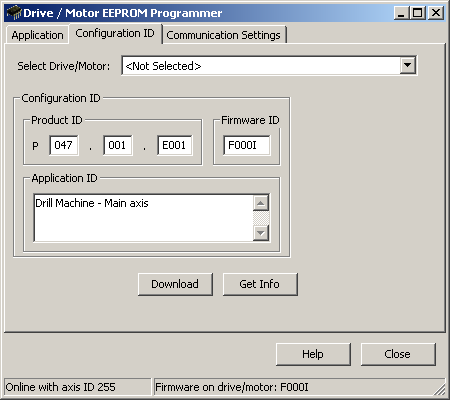

In the Configuration ID tab, by pressing the Get Info button, you get the drive/motor configuration ID including the product ID, the firmware ID, the EEPROM size and the application ID.

The product ID uniquely identifies the drive/motor execution. This information is written by Technosoft in the last EEPROM memory locations in especially reserved locations. In these locations Technosoft also puts the product EEPROM size in 16-bit Kwords and the required firmware ID. The main goal of this information is to protect against accidental wrong programming of the EEPROM memory or in the case of very big TML programs against bypassing the EEPROM capacity. Both EasySetUp and EasyMotion Studio perform the following verifications every time a setup data or a motion application has to be downloaded.

| 1) | The product ID of the application/setup data to download matches with the product ID stored in the drive/motor EEPROM, or is set as being compatible |

| 2) | The required firmware of the application/setup data to download has the same number as the drive/motor actual firmware and either the same or a lower revision |

The download is performed only if both conditions are true. The application ID is a space reserved for a text of up to 40 characters which you can program. Its main goal is to help you quickly identify the setup data uploaded from a drive/motor. In order to program an application ID, edit your text in the Application ID field and press the Download button.

The configuration ID tab may also be used to reprogram the product ID, the required firmware ID and the EEPROM size, if by mistake, the area reserved for this information in the EEPROM memory is erased. In this case, select the product name from the list, add your application ID (if it is the case) and press the Download button.

In the Communication Settings tab, you can set the communication type and parameters as well as the EEPROM write protection degree. When you launch the EEPROM Programmer, it tries to communicate with your drive/motor using your last communication settings. If the communication attempt fails, the EEPROM Programmer opens automatically the Communication Settings tab, where you can setup the communication parameters(HELP_COMMUNICATION_SETUP@EasySetup.hlp). Each time when you’ll try to switch to the other tabs, the communication is checked and the other tabs are opened ONLY if the communication is established.

If your application does not require storing data in the drive/motor EEPROM at runtime and you don’t intend to change the setup parameters from your host and then to save the changes in the drive/motor EEPROM, you can write protect the entire EEPROM after you download the .sw file. This is an extra protection against accidental wrong commands that may modify EEPROM locations. If your application requires to store data at runtime but you don’t and you don’t intend to change the setup parameters and maybe cam tables (if present) you can write protect only the last quarter or last half of the EEPROM and allow the write operation for the rest.

See also: